heavy rail vehicle friction air brake tests pdf|code of air brake testing : white label low-pressure position. The test device must be coupled to a 1700-in.3 test volume (equivalent to 110 ft of brake pipe) charged to 80 psi. The test volume will have a choke or . Resultado da O Outro Lado do Paraíso. 14. Novela. Clara vive uma vida simples no Jalapão com o avô até que uma paixão a leva do céu ao inferno. Ela conhece Gael, herdeiro de uma família .

{plog:ftitle_list}

webJK Bar em Pelotas - menu, ⏰ horário de funcionamento, ☎️ número de telefone, 📍 endereço e mapa.

This Guide provides brake and stability performance ratings for truck and trailer combinations, with varying brake technologies. It aims to assist the Australian road transport sector to . low-pressure position. The test device must be coupled to a 1700-in.3 test volume (equivalent to 110 ft of brake pipe) charged to 80 psi. The test volume will have a choke or .

Condition based monitoring concepts for railway brake systems offer a row of promis-ing advantages: improved safety, reduced noise emission, and economic benefits by an optimal .Adopted: October 6, 2021 Revised: June 10, 2022. Abstract: This recommended practice provides a methodology and a standardized form for maintaining car equipment operated by Tourist, .

There are two options for testing the performance of rail vehicles and the application of material to the wheel/rail interface to influence friction, and therefore braking performance, in a low .Test brake pipe integrity using either the Air Flow Method (AFM) or Brake Pipe Leakage Method when conducting any of the following: • Class I Brake Test (Initial Terminal)

simulations and field testing of an articulated heavy vehicle. The observer was found to operate robustly during single-wheel vehicle simulations, and provide reasonable estimates of surface .This study reviews the practice of brake tests in freight railways, which is time consuming and not suitable to detect certain failure types. Public incident reports are analysed to derive a .

AURHTB001 – Diagnose and repair heavy vehicle air braking systems – Resource AUR16-V1 Aug 2016 5 of 65 © MTA Institute of Technology Never use compressed air to remove dust .

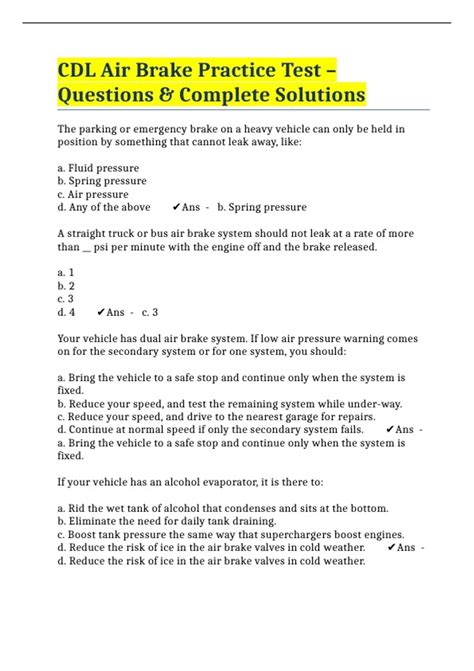

pneumatic brakes are sometimes referred to as “air brakes.”A pneumatic brake system is a power braking system with compressed air as the operating medium. In the pneumatic friction . Drivers greatly rely on their brakes when hauling thousands of pounds of weight in trucks. The braking system on large trucks, buses, and tractor-trailers consists of air brakes. Air-powered brakes are the safest . The velocity-dependent friction of brake friction composites is investigated, focusing on the contact area on the sliding surface. Friction tests were performed using a reduced scale brake . The correlation between the wear behavior of a heavy commercial vehicle (HCV) brake liner tested under controlled laboratory conditions and that in actual field conditions is investigated.

The project implementation is aimed not only at the solution of one separated, even though very topical and important issue (wheel tread wear).It enables to create presuppositions for performance of new projects aimed at the study of wear wheel/ rail in contact, new wheel or rail profiles development [2, 3, 5 and 6] wheel/rail couple adhesion .

extech moisture meter service

code of air brake testing

The novel brake valve installation and the test vehicle (featured in the BBC footage) are shown in the following two gures. Figure 1.1: Fast-acting brake valve (FABV) modulators installed on a Volvo FH12 tractor unit for vehicle testing Figure 1.2: Test vehicle ( tted with FABVs) carrying out brake-in-turn test on wet basalt surface. Reduction of noise due to rolling contact of wheel and rail for fright cars is one of the principal tasks of the European railways to be solved. Experts of railways, industries and universities were engaged during the last about ten years to search for technical solutions. An important noise reduction of fright cars can be achieved by replacing the cast iron brake shoes .

Figure 4.1 shows the classification of brakes on rail vehicles. Brakes with contact are divided into free-acting and wheel-rail friction brakes. The mechanical brakes are divided as friction brakesinto blockbrakes, disc brakesand –more rarely –drum brakes.The block brakeis still senger rail vehicles use disc brake. The disc braking systems pro- . brake tests and that wear checks of the brake disc and brake pad. . to rail, brake blocks, environment air, residual .5.2.3 Hydraulic Brake System with Air Assistance STATIC TEST DYNAMIC TEST a) All dynamic tests as given in 5.2.1. 5.2.4 Air Brake System STATIC TEST a) All static tests as given in 5.2.3. DYNAMIC TEST a) All dynamic tests as given in 5.2.1. 5.2.5 Vehicle with Anti-lock Brake System For the test related with ABS, see IS 11852 (Part 9). 6 VISUAL .

The use of friction linings and pads in friction brakes of rail vehicles need now to take a milestone towards the adaptation of composite synthetic materials in order to reduce noise, which is .

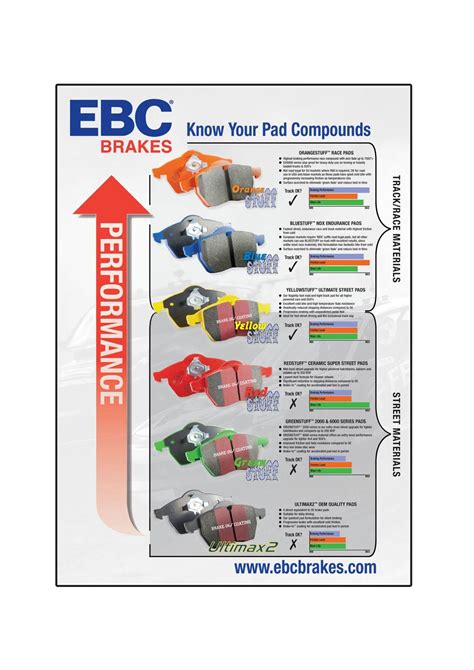

Truck air-actuated disc brake. An air brake or, more formally, a compressed-air-brake system, is a type of friction brake for vehicles in which compressed air pressing on a piston is used to both release the parking/emergency brakes in order to move the vehicle, and also to apply pressure to the brake pads or brake shoes to slow and stop the vehicle. Air brakes are used in large .Commercial Vehicles Air disc brake pads and drum brake linings for bus, trailer, truck and special purpose vehicles . commuter and national rail systems. Bremskerl friction materials are RoHS and REACH compliant. Contents . Data determined by small scale brake lining tests, may not be compatible to practice and further tests may be In this sense we compared two friction materials used for brake pads for small and medium-sized vehicles. Braking tests were performed on a vehicle with a spark-ignition engine and two variants of .

Brake disc surface after fatigue test UltraPad Flex pad friction surface after fatigue test n Weight reduction of ~70 kg in relation to a standard steel wheel-mounted brake disc nEnergy savings due to reduced weight (particularly significant in the case of a metro application) n Fatigue tests for Chinese-standard regional commuter application .Part 2: Methods of test. UIC 540 – Air Brakes for freight trains and passenger trains. UIC 541 – 02/03/04 – Brakes – Regulations concerning manufacture of the different brake parts. UIC 544-1 – Braking power. TSI – Rolling Stock – .

Hydraulic motor braking (rail wheel), hydraulic disc / tread braking (rail wheel), spring applied park brake (rail wheel). TYPE 2 VEHICLES – FRICTION DRIVE : Hydraulic disc / tread braking (rail wheel), spring applied park brake (rail . wheel). TYPE 3A – RAIL GUIDANCE : Road wheel hydraulic disc braking (rubber wheel on rail), hydraulic disc /

The wear and rolling contact fatigue (RCF) testing approaches for wheels and rails have been reviewed and evaluated in this study. The study points out the advantages and limitations of the existing approaches. The broad analysis revealed that scaled laboratory-based wear testing is widely applied. However, it is necessary to predetermine the input parameters . The simulation system performs a synchronous simulation of the air brake and the longitudinal train dynamics. The simulation system models the locomotive automatic brake valve and car brake .

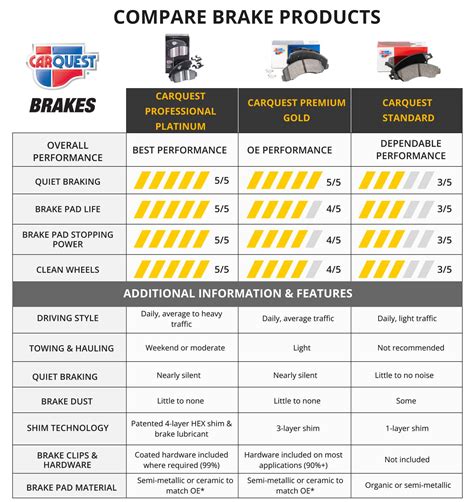

braking and stability chart

The use of friction linings and pads in friction brakes of rail vehicles need now to take a milestone towards the adaptation of composite synthetic materials in order to reduce noise, which is . The correlation between the wear behavior of a heavy commercial vehicle (HCV) brake liner tested under controlled laboratory conditions and that in actual field conditions is investigated. A brake liner study for friction and wear is performed on an inertia brake dynamometer (IBD) at different temperatures (200 °C, 250 °C, and 300 °C) using 6000 brake .next generation of compact disc brake caliper unit for rail vehicle...172 z. csemez analysis of . inertia dynamometer rotor crack test procedure for air disc brakes...526 c. agudelo, d. dharaiya . standardization of drag mode friction test for hydraulic and

leverage that potential through innovations in brake control. Knorr-Bremse’s Reproducible Braking Distance (RBD) concept is based on factoring wheel-rail adhesion and deceleration into the brake control system. Feasibility tests on the wheel-rail adhesion test rig demonstrated that, even under extremely unfavorable There are two options for testing the performance of rail vehicles and the application of material to the wheel/rail interface to influence friction, and therefore braking performance, in a low . What is Air Brake System? Fig 1: Air braking system. An air brake system, also known as a compressed air brake system, functions as a friction brake in vehicles, employing compressed air on a piston to exert the necessary pressure on brake pads for vehicle cessation. These brakes find prominence in sizeable, weighty vehicles, especially those with multiple . The effectiveness of the braking changes as the friction condition at the wheel-rail interface and speed of rail vehicle change. The conventional brake control systems do not differentiate these .

Section 2 - Brakes National Heavy Vehicle Inspection Manual V3.0 4 of 6 h. The parking brake is inoperative or on a vehicle with a reserve air tank is unable to be released at least once i. Air reservoir drain valves on reservoirs do not work properly cannot be . 3.1 Train modelling. Modelling of LTD usually assumes that there is no lateral or vertical movement of the vehicles. Based on this simplification, the forces considered in the train system include traction forces, dynamic brake forces, air brake forces, in-train forces (coupler forces), propulsion resistance, curving resistance and gravitational components.

extech moisture meter set

web8 de fev. de 2024 · 100K+. Downloads. Everyone. info. Install. About this app. arrow_forward. Discover the paths to follow in your career, where .

heavy rail vehicle friction air brake tests pdf|code of air brake testing